Thermal Spraying

Thermal spraying

Thermal spray coating makes it possible to provide individual components with functionally appropriate surfaces. A wide range of materials can now be given a protective surface using thermal spraying. Metals are particularly suitable as coating substrates.

A renowned supplier of equipment for the textile industry, MEMMINGER-IRO has used this coating technology for over 20 years. It is one of the company's core skills in the sector of production processes for wear protection and functional surfaces.

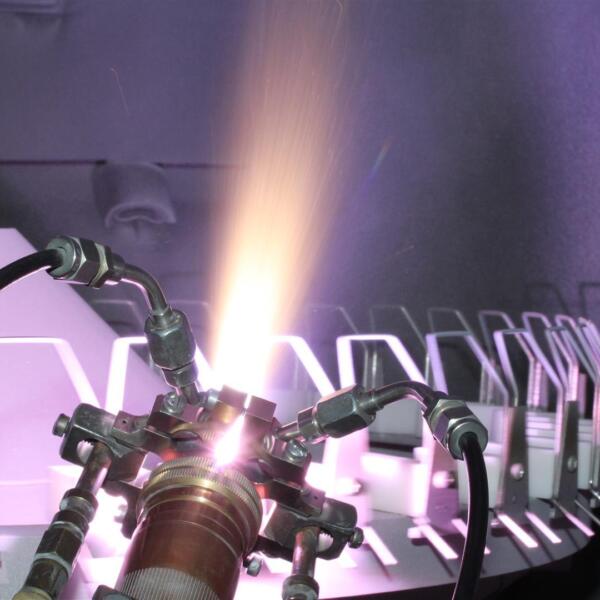

Plasma spraying

Air plasma spraying (APS)

Plasma spraying can be used for a wide range of applications. This versatility makes it the thermal spraying technique of choice. The coating material is fed in powder form to the plasma torch. The individual spray particles are melted in the plasma jet and sprayed onto the activated surface of the substrate.

Treatment using materials with high melting points presents no problems. Despite the fact that torch temperatures can reach 20,000 °C, components can be treated even when they are close to ambient temperature. Previous heat treatment of metallic material is not effected by the plasma coating process. The coating thickness provided by plasma coating depends on the substrate, the coating material used and the geometry of the workpiece.

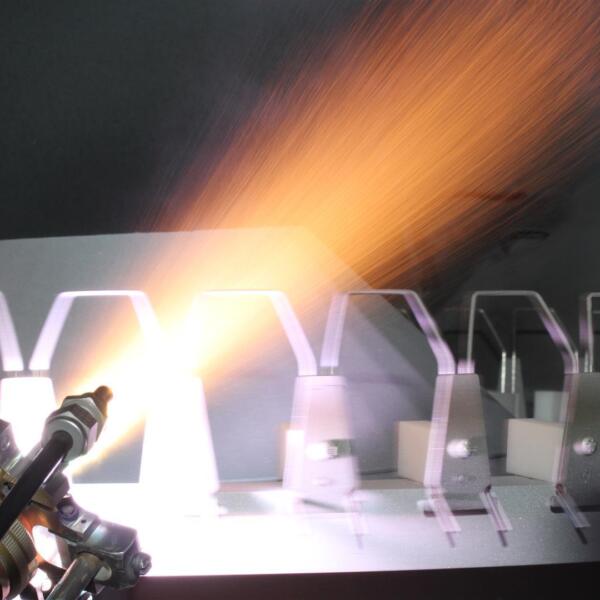

Flame spraying

Wire flame spraying

Wire flame spraying involves continuously melting a spraying consumable in wire form as it is fed through the centre of a fuel gas-oxygen flame. The wire is fed to the flame by a feed unit. With the help of an atomizing gas, droplets of spray particles are fired onto ready-prepared workpiece surfaces. This process is particularly suitable for producing metallic coatings.

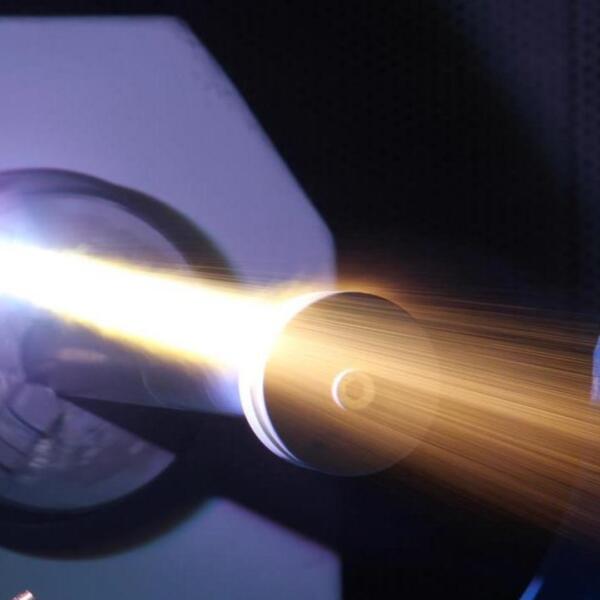

Powder flame spraying

In the powder flame spraying process a spraying consumable in powder form is injected into a fuel gas-oxygen flame and applied to the ready-prepared workpiece surfaces. A distinction is made between standard powder flame spraying and powder flame spraying with thermal post-treatment. The process involving thermal post-treatment is particularly suitable for preparing components where a high degree of corrosion protection and chemical resistance is required.

Properties / Advantages

- Coating thicknesses of several millimetres are possible.

- Particularly suitable for the repair of bearing seats.

- Coating material: mainly metallic and plastic material.