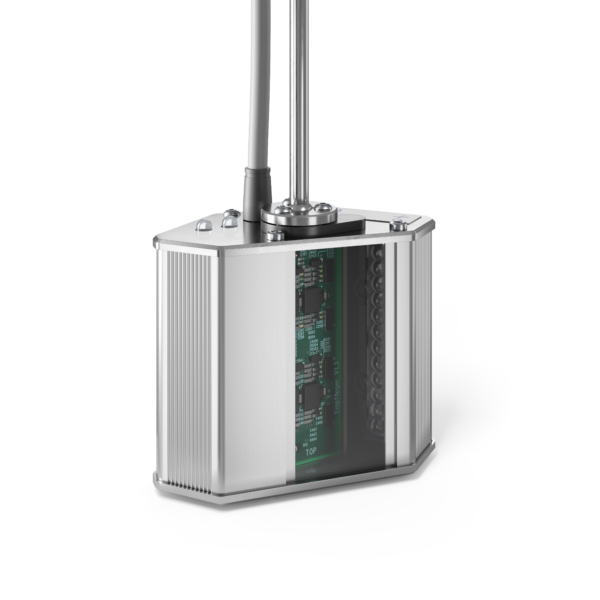

KNIT SCAN - Fabric Scanner

Application

Needle faults are expensive. The quicker they are detected, the more you save. The KNIT SCAN system detects needle line faults and holes and it stops the machine after detection of these faults.

The scanner is installed in vertical position with a distance of about 15mm to the fabric. Faults are detected by using the light reflection principle. The light emitted by the scanner is reflected back by the fabric and the resulting signal received by the scanner is processed in order to detect faults. The scanner automatically adjusts to the surface of the fabric currently being scanned. It can be used for different single jersey circular knitting machines producing various types of plain fabrics.

Main features

- Reduces production of second quality fabric

- Simple adjustment through handterminal

- Cutting lines are detected automatically and can be ignored if required

- No touching of the fabric

- Easy installation and handling

- No wear and tear of the scanner by touching fabrics

- Portable handterminal

| Technical data | |

|---|---|

| Power supply: | 24 V AC 50/60 Hz |

| Voltage range | 19-33 V AC/DC 50/60 Hz |

| Run signal (machine running) | 19-33 V DC |

| Max. power | 10 VA |

| CANopen interface: | CAN GND, CAN H, CAN L |

| Weight | Scanner: 450 g |

Submit your data and you will be contacted by one of our experts